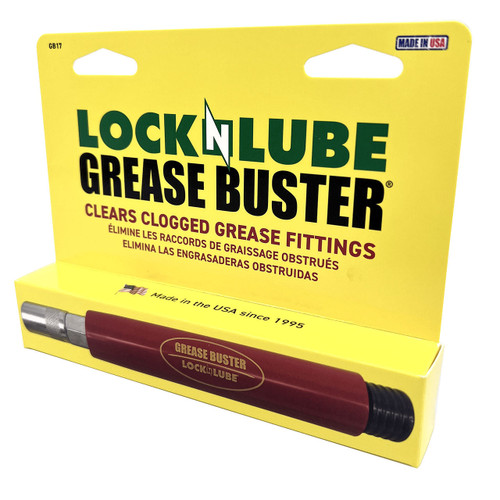

Product Description

Open up clogged grease fittings with the Grease Buster®. Simply fill with a solvent and tap the piston with a hammer. The updated design includes a textured grip and two O-rings on the piston. Cleans and flushes out old dried grease from fittings, pins, shafts, bushings, and joints. Manufactured by LockNLube in the USA.

- Cleans and flushes out old dried grease from fittings, pins, shafts, bushings, and joints

- Uses penetrating fluid and hydraulic pressure

- Reduces downtime. Much cheaper than new bearings!

- Hose extension and pneumatic piston available

- Not for use with sealed bearings

The Grease Buster’s piston, included with the product, is hollow and should be filled with a liquid (not aerosol) penetrating oil. Seat the piston in the Grease Buster, attach the coupler to your Zerk fitting, and tap the piston with a hammer. This forces the penetrating oil into the fitting and loosens it for regular greasing.

For customers with a pneumatic hammer, they might prefer using the pneumatic piston (sold separately) instead of the standard piston.

The Original Grease Buster® is the answer to a problem that many people have lived with for a long time. Plugged-up grease fittings and bearings are a problem common in machinery. One greases a machine and the grease can dry out before the machine is used again. The tool consists of a heavy-duty adjustable hydraulic coupler, cylinder, and a piston with a knob.

Instructions: Remove the piston. Fill the cylinder by pouring in penetrating oil. Start the piston back into the cylinder. Place the tool onto the grease fitting and by tapping the piston, forcing the solvent into the fitting and or bearing. The key word is TAP. Using a lightweight hammer and small, rapid taps, work the penetrating oil into the fitting. You’re trying to dissolve the clog, not blast it out of the way. Repeat if necessary.